Introduction

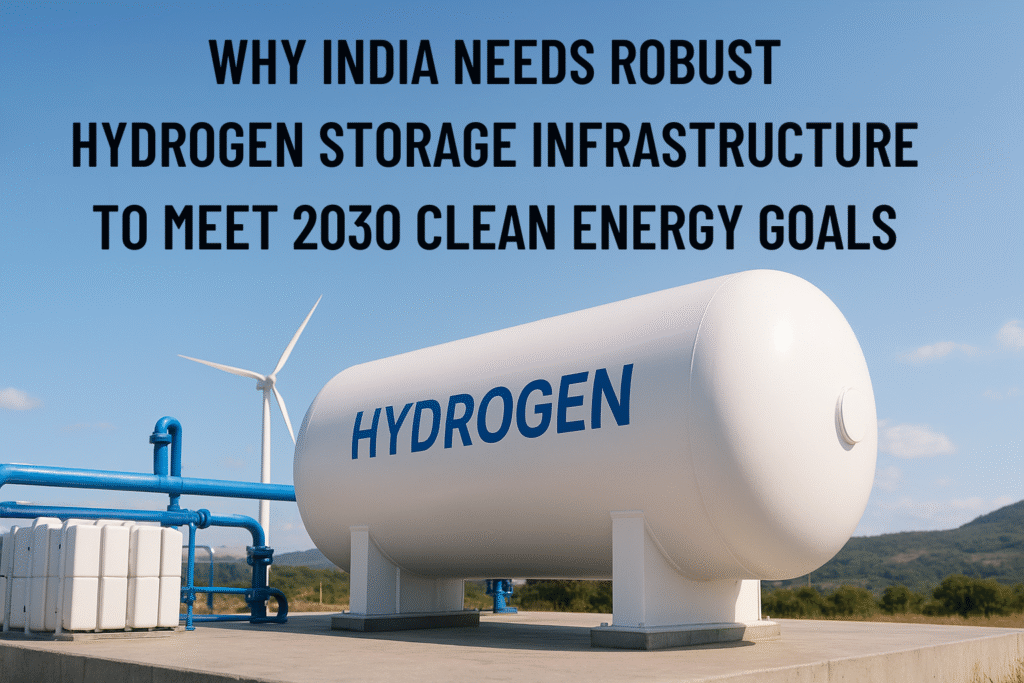

As India accelerates its clean energy transition, hydrogen has emerged as a cornerstone of the nation’s strategy for decarbonization. With ambitions to achieve net-zero emissions by 2070 and interim renewable energy targets by 2030, hydrogen is increasingly seen as a key enabler across industries, transport, and power generation.

However, one critical challenge threatens to slow down India’s hydrogen ambitions: the lack of robust hydrogen storage infrastructure. Efficient, safe, and scalable storage solutions are essential to ensure that hydrogen can be reliably produced, transported, and utilized when and where it is needed.

Developing this infrastructure is not just a technical necessity — it is a strategic imperative for India’s energy security, industrial competitiveness, and climate goals.

Why Hydrogen Storage is Crucial for India

Unlike conventional fuels, hydrogen poses unique storage and transportation challenges due to its low volumetric energy density and high flammability. Effective storage solutions enable:

- Reliable Supply: Smooths out the intermittent availability of green hydrogen produced from renewable energy sources like solar and wind.

- Grid Balancing & Energy Security: Large-scale storage allows hydrogen to act as an energy buffer, supporting India’s power grid during peak demand.

- Sector Coupling: Enables integration of hydrogen across heavy transport, steel, cement, and chemical industries.

- Export Readiness: Robust storage infrastructure is key for making India a global hub for green hydrogen exports.

Without adequate storage, India risks underutilizing its hydrogen production capacity, delaying decarbonization efforts in critical sectors.

Current Hydrogen Storage Landscape in India

India’s hydrogen storage infrastructure is still at a nascent stage:

-

Limited Industrial Storage: Most hydrogen produced today is used immediately in industrial processes with minimal storage capacity.

- Early-Stage Pilot Projects: Indian Railways, oil refineries, and select OEMs are testing small-scale storage solutions for mobility and energy applications.

- Regulatory Frameworks: The Petroleum and Explosives Safety Organization (PESO) has defined safety standards, but widespread adoption requires more standardized storage codes and incentives.

- Technology Gaps: Advanced storage methods such as liquid hydrogen, metal hydrides, and high-pressure tanks are mostly imported, limiting domestic manufacturing capability.

This nascent stage emphasizes the urgent need for scaling storage technologies alongside production and distribution networks.

Key Challenges in Hydrogen Storage

Scaling hydrogen storage in India faces multiple technical and economic challenges:

- High Capital Cost: Advanced storage systems require significant upfront investment, especially for cryogenic or high-pressure solutions.

- Safety Concerns: Hydrogen is highly flammable; storage systems must meet stringent PESO and BIS safety standards.

- Energy Losses: Compression and liquefaction of hydrogen consume energy, impacting overall efficiency.

- Technology Localization: India currently imports a majority of high-pressure tanks, electrolyzers, and liquefaction equipment, making domestic scaling expensive.

- Logistics & Infrastructure Gaps: Lack of hydrogen pipelines and refueling stations increases reliance on transport, which is expensive and energy-intensive.

Emerging Solutions and Innovations

India’s research and industrial ecosystem is actively working to address these challenges:

- Advanced Storage Materials: Development of metal hydrides, chemical carriers, and liquid organic hydrogen carriers (LOHC) for safer and denser storage.

- Green Hydrogen Hubs: Renewable-powered hydrogen production clusters with integrated storage facilities are being piloted along industrial corridors.

- Public-Private Partnerships (PPP): Government and industry collaboration to build scalable storage and distribution networks.

- Hybrid Storage Systems: Combining compressed, liquid, and solid-state storage to optimize efficiency and cost.

- Incentives & Policy Support: Under the National Green Hydrogen Mission, financial support is being offered for storage technologies, equipment manufacturing, and R&D.

Roadmap for 2030: Scaling Hydrogen Storage

To meet India’s 2030 clean energy goals, hydrogen storage infrastructure must evolve rapidly:

- Expand Industrial Storage: Refineries, fertilizer plants, and steel factories need large-scale on-site storage.

- Enable Mobility Solutions: Hydrogen refueling stations for trucks, buses, and trains require dedicated storage tanks with high safety standards.

- Standardize Safety & Codes: Nationwide adoption of PESO-compliant storage regulations for industrial, transport, and domestic use.

- Develop Domestic Manufacturing: Encouraging local production of tanks, compressors, and cryogenic systems to reduce import dependency.

- Integrate with Renewable Energy: Co-locating storage with solar and wind farms to stabilize intermittent generation and provide round-the-clock hydrogen availability.

A robust hydrogen storage ecosystem will ensure that India’s green hydrogen ambitions are practical, scalable, and aligned with industrial and mobility requirements.

Conclusion

Hydrogen holds the potential to revolutionize India’s clean energy landscape. Yet, production alone is insufficient — without robust storage infrastructure, the promise of hydrogen will remain partially unfulfilled.

Investing in safe, scalable, and efficient hydrogen storage solutions will enable India to meet its 2030 renewable targets, decarbonize transport and industry, and secure energy independence. By combining technology innovation, policy support, and public-private collaboration, India can emerge as a global leader in green hydrogen and its storage ecosystem, paving the way for a sustainable, net-zero future.